Recognizing Steel Shops: Trick Truths and Insights for Industry Professionals

Steel factories play a vital role in the manufacturing field, specifically in sectors like automotive and aerospace. They convert resources into necessary elements via various casting processes. Comprehending these procedures, in addition to the products and quality assurance actions entailed, is essential for industry experts. As difficulties and technological innovations arise, the landscape of steel shops is advancing. What implications do these adjustments hold for the future of the industry?

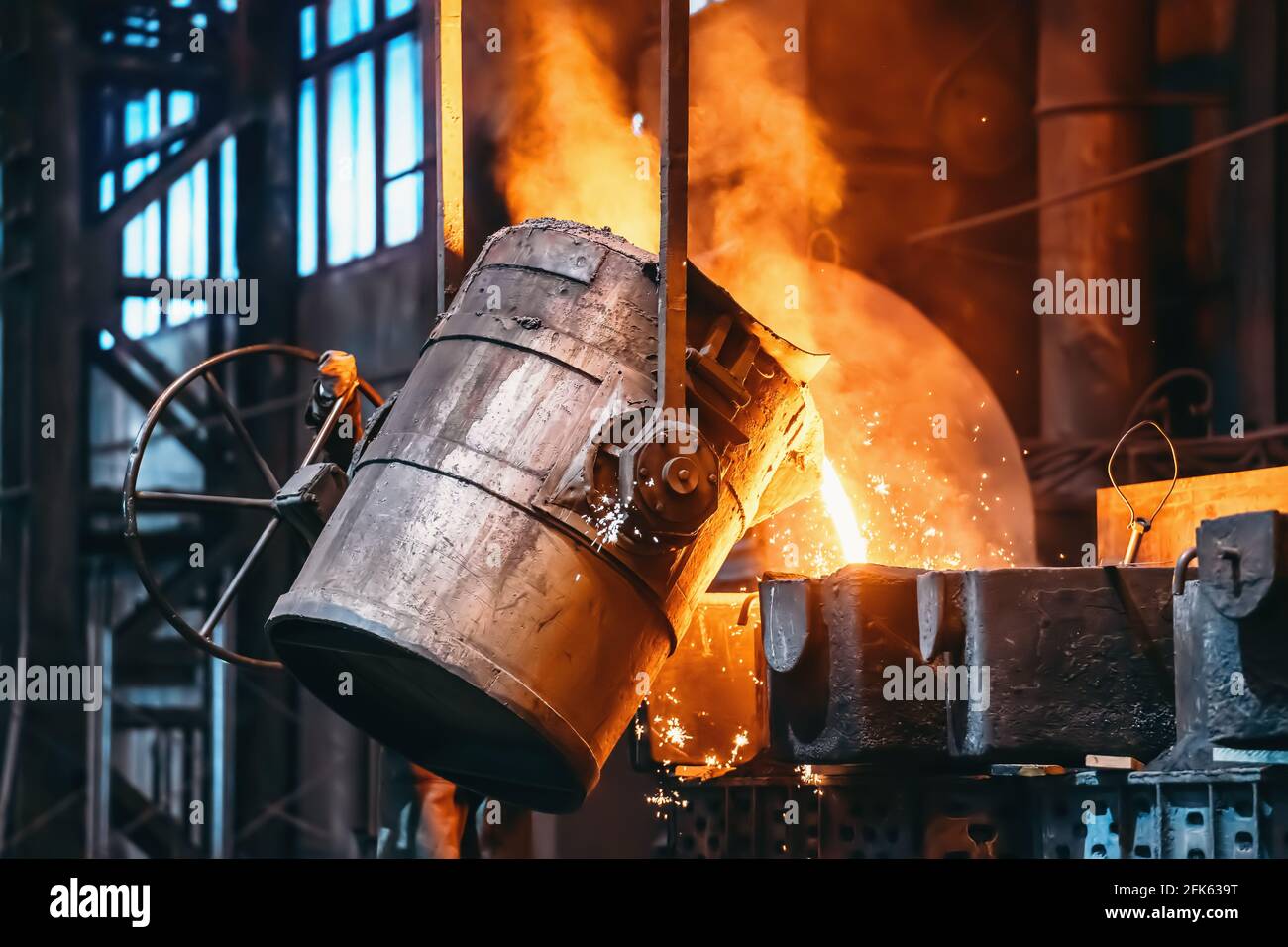

The Duty of Metal Factories in Production

Steel shops act as an important foundation in the manufacturing industry, transforming resources into vital elements. They play a considerable role in numerous sectors, including automobile, aerospace, and building and construction, by supplying high-quality metal components that meet details efficiency requirements. Shops make use of advanced methods to melt steel and cast it into preferred forms, guaranteeing accuracy and toughness.

The process starts with the choice of resources, such as bronze, iron, or aluminum, which are after that heated up to severe temperature levels. Proficient professionals look after the entire operation, from mold and mildew style to top quality control, ensuring that each part sticks to industry guidelines and customer specifications.

Furthermore, metal factories add to the economic climate by developing work and sustaining regional supply chains. Their ability to adjust and introduce to altering market demands strengthens their value, making them important to the manufacturing landscape.

Sorts Of Steel Casting Procedures

Metal spreading processes play a vital role in the factory industry, with numerous techniques tailored to details requirements. Among these, sand spreading techniques and financial investment spreading methods are extensively made use of for their distinctive advantages and applications. Comprehending these procedures is crucial for enhancing production and guaranteeing quality in steel parts.

Sand Casting Techniques

Just how do sand spreading methods stand out amongst various steel casting procedures? Sand casting is renowned for its flexibility and cost-effectiveness, making it a preferred approach in different industries. This strategy uses sand as the main mold and mildew product, enabling intricate sizes and shapes to be produced with family member ease. The procedure starts with developing a pattern, which is then bordered by sand blended with a binder. Aluminum Casting. After the mold and mildew is developed, molten steel is gathered, solidifying to develop the desired part. One of the significant benefits of sand spreading is the capability to cast large parts, which is often tough for various other techniques. With its versatility and uncomplicated setup, sand casting continues to be a keystone of metal shop operations

Financial Investment Casting Techniques

While various casting approaches exist, investment casting is identified by its capability to create intricate forms with exceptional accuracy. This procedure, typically referred to as lost-wax spreading, entails developing a wax pattern that is covered with a ceramic product. As soon as the ceramic hardens, the wax is thawed away, leaving a hollow mold and mildew for metal to be poured right into. Investment spreading masters generating great information and intricate geometries, making it suitable for sectors such as aerospace, automobile, and clinical. The liquified metal solidifies and loads the mold, resulting in high-quality elements with marginal post-processing required. Its adaptability allows for a range of products, consisting of steel, light weight aluminum, and brass, additional improving its appeal in manufacturing sophisticated parts.

Products Made Use Of in Metal Factories

In addition, shops make use of different alloys, which can boost particular residential properties like stamina and resistance to use. The choice of molding products, such as sand, ceramic, or steel, is additionally crucial, as these establish the high quality of the actors surface area and dimensional accuracy. Ultimately, finishes and ingredients are employed to boost casting performance, lessen issues, and help with the splitting up of the cast item from the mold. Each product adds to the effectiveness and effectiveness of the factory process.

Quality Assurance Actions in Shop Operations

Quality assurance actions in shop operations are important for ensuring the integrity and performance of actors metal products. Various assessment techniques and developed standards play a crucial role in identifying potential defects early in the production process. Additionally, applying efficient defect prevention approaches can greatly enhance product quality and reduce waste.

Evaluation Techniques and Requirements

Effective evaluation strategies and criteria are essential for keeping the integrity of steel factory procedures. These techniques ensure that products fulfill specified high quality specifications and adapt sector laws. Typical evaluation methods include aesthetic assessments, dimensional checks, and non-destructive screening (NDT) methods such as ultrasonic and radiographic screening. Each method offers to identify flaws or incongruities without jeopardizing the product. Sticking to well established criteria, such as ISO 9001 and ASTM guidelines, helps standardize examination procedures and promotes consistency throughout procedures. In addition, normal training of employees on these requirements boosts the effectiveness of the evaluation process. Ultimately, extensive evaluation methods and conformity with requirements are essential in providing high-grade castings and ensuring client fulfillment in the factory sector.

Issue Avoidance Techniques

Maintaining high criteria of top quality in steel factory operations requires the execution of durable problem prevention techniques. These techniques concentrate on try these out identifying prospective sources of flaws early in the manufacturing process. Secret procedures consist of rigorous material choice, specific control of melting and putting conditions, and adherence to standardized operating procedures. Regular training of personnel guarantees that employees are well-informed regarding best methods and the most up to date innovations. In addition, utilizing sophisticated simulation software application can anticipate possible problems prior to they take place. Continuous monitoring through in-process examinations and quality assurance checks permits instant corrective actions, minimizing the likelihood of issues getting to the end product. Eventually, an aggressive technique to problem avoidance cultivates integrity and improves customer satisfaction in metal foundry operations.

Typical Difficulties Faced by Steel Factories

Metal foundries play an important role in numerous sectors, they typically experience considerable challenges that can impact their procedures. One main problem is the fluctuation in basic material costs, which can impact productivity and spending plan projections. Additionally, shops frequently deal with labor lacks, as knowledgeable employees are progressively tough to discover and maintain, leading to potential ability gaps in production procedures.

Environmental laws additionally posture challenges; foundries have to adhere to rigid requirements, which may require pricey financial investments in air pollution control innovations. Moreover, preserving high-grade requirements is essential, as defects in spreading can lead to item remembers and reputational damage. The complexity of handling supply chains, specifically during global disturbances, can impede timely manufacturing and shipment. Jointly, these challenges require critical planning and adaptive management to assure the ongoing feasibility and success of metal factories in an open market

Technological Developments in Steel Casting

As steel foundries seek to boost efficiency and reduce prices, technical advancements in steel spreading have become vital innovations. The integration of computer-aided layout (CAD) and simulation software program has revolutionized the layout procedure, enabling precise modeling of cast elements and the identification of potential problems before production begins. Advancements in 3D printing technology enable the rapid prototyping of cores and molds, considerably reducing lead times and product waste.

The adoption of automated systems and robotics in the casting process has actually boosted consistency and performance, while additionally reducing human mistake. In addition, sophisticated materials, such as high-performance alloys, are being developed to hold up against severe conditions, boosting the resilience of actors products. These technological advancements not only streamline operations yet likewise add to even more sustainable practices within the market, eventually positioning steel foundries to meet the developing needs of their clients properly.

Future Patterns in the Steel Foundry Sector

With the ongoing development of the metal shop market, several future trends are poised to reshape its landscape significantly. Automation and robotics are expected to boost manufacturing efficiency, reducing labor costs and enhancing accuracy in casting processes. Furthermore, the adoption of advanced materials, such as lightweight alloys and compounds, will certainly deal with the growing demand for lasting and high-performance parts in different industries, including vehicle and aerospace.

The integration of digital technologies, such as the Internet of Things (IoT) and fabricated knowledge (AI), will facilitate real-time check my site surveillance and anticipating upkeep, leading to boosted functional efficiency. The focus on sustainability will drive the growth of environment-friendly techniques, consisting of the recycling of scrap steel and the decrease of power consumption in shops. Ultimately, workforce development will end up being important as the industry looks for proficient labor to adapt to these technical innovations, guaranteeing an affordable edge in the global market.

Frequently Asked Questions

What Certifications Are Necessary for Steel Foundry Workflow?

How Do Foundries Take Care Of Environmental Laws?

Shops manage ecological policies by executing complete compliance programs, conducting routine audits, utilizing air pollution control technologies, and training workers on best practices. They additionally keep open communication with regulatory firms to assure adherence to progressing ecological criteria.

What Are the Common Lead Times for Casting Manufacturing?

Typical preparation for casting production variety from a few weeks to several months, depending on factors such as complexity, material demands, and shop capacity. Reliable planning and interaction can help in reducing these lead times considerably.

Exactly How Do Shops Handle Workforce Training and Security?

Foundries focus on workforce training and safety via thorough programs, routine workshops, and adherence to safety laws. They implement hands-on training, mentorship, and continual assessments to guarantee workers are well-prepared for safe operational practices in difficult atmospheres.

What Is the Influence of Global Supply Chain Issues on Foundries?

International supply chain issues substantially influence foundries by causing material shortages, boosting expenses, and delaying manufacturing timelines. These interruptions urge factories to adapt their sourcing strategies and improve stock administration to keep functional efficiency.

Steel foundries play a vital duty in the manufacturing field, especially in markets like automotive and aerospace. Steel foundries offer as a vital foundation in the manufacturing industry, changing raw products browse around these guys right into crucial parts. Steel casting procedures play an essential duty in the factory sector, with numerous techniques tailored to specific needs. Steel factories play an essential function in different industries, they usually encounter significant challenges that can influence their procedures. As steel foundries look for to enhance efficiency and lower expenses, technological improvements in steel casting have actually emerged as vital developments.